Infrastructure

Infrastructure Facilities

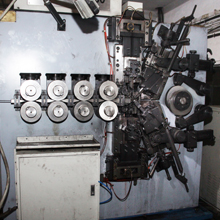

Our organization is supported with advanced infrastructure facility, which is speeded across a wide area and is divided in different units. These units include manufacturing unit, research and development unit, quality testing unit and warehouse and packaging unit.

We also have well developed machines and technology to manufacture industry standard Metal Springs. Owing to the support of this unit, we are capable of providing high quality products to our clients at competitive prices.

Machine and Tool - Room Details

| Sr. No. | Machinery Description | Range | Nos. |

| 01 | Automatic Spring Coiling Machine (comp) | 3.50 to 12.00mm | 01 |

| 02 | Automatic Spring Coiling Machine (comp) | 2.50 to 8.00mm | 01 |

| 03 | CNC Coiling Machine | 3.00MM TO 8.00MM | 01 |

| 04 | CNC Coiling Machine | 0.30MM TO 3.00MM | 01 |

| 05 | CNC Sping Forming Machine | 0.50MM TO 3.50MM | 01 |

| 06 | Automatic Spring Coiling Machine (comp) | 2.00 to 6.00mm | 01 |

| 07 | Automatic Spring Coiling Machine (comp) | 1.50 to 5.50mm | 02 |

| 08 | Automatic Spring Coiling Machine (comp) | 0.80 to 4.00mm | 01 |

| 09 | Automatic Spring Coiling Machine (comp) | 0.80 to 3.00mm | 02 |

| 10 | Automatic Spring Coiling Machine (comp) | 0.40 to 2.20mm | 01 |

| 11 | Automatic Spring Coiling Machine (comp) | 0.10 to 1.50mm | 01 |

| 12 | Automatic Spring Coiling Machine (comp) | 0.10 to 1.20mm | 01 |

| 13 | Torsion Spring Coiling Machine | 0.50 to 2.50mm | 02 |

| 14 | Torsion Spring Coiling Machine | 1.50 to 6.00mm | 01 |

| 15 | Carlson Hand Coiling M/C | 0.5 to 4.00mm | 01 |

| 16 | Automatic End Grinding M/C | 0.50mm to 3.00mm | 01 |

| 17 | Auto Down Feed End Grinding M/C | 2.00mm to 12.00mm | 04 |

| 18 | Automatic Wire Straitening & Cutting M/C | 0.8 to 8.00mm | 02 |

| 19 | Heat Treatment Furnace | 0 to 450 0C | 01 |

| 20 | Conveyor Belt Furnace | 0 to 450 0C | 01 |

| 21 | Zigzag Spring Forming Machine | Up to 5.00mm | 01 |

| 22 | Insert Wire Forming Machine | Up 2.00mm | 01 |

| 23 | Hydraulic Press | 25 ton | 01 |

| 24 | Hydraulic Press | 16 ton | 01 |

| 25 | Power Press | 30 MT | 01 |

| 26 | Hand Press | 0 to 3 No. | 10 |

| 27 | Loop Bending Fixture | 1 to 3.0mm | 01 |

| 28 | Bending And Cutting Dies | As per requirement | -- |

| 29 | Shot Pinning Machine | 100 Kg | 01 |

| 30 | Shot Pinning Machine | 250 Kg | 01 |

| 31 | Lathe Machine | 6Feet | 01 |

| 32 | Bench Grinders | 2 HP | 03 |

| 33 | Drill Machine | 25 mm | 01 |

| 34 | Slotting Machine | 2 HP | 01 |

| 35 | Id Chamfering Machine | 1.5 Hp | 02 |

Inspection Facilities

| Sr. No. | Machinery Description | Range | Least Count | Nos. |

| 01 | Load Testing Machine | 0 to 5 kgf | 0.1 kgf | 01 |

| 02 | Load Testing Machine | 0 to 50 kgf | 0.2 kgf | 01 |

| 03 | Load Testing Machine | 0 to 120 Kgf | 0.01 kgf | 01 |

| 04 | Vernier Caliper | 0 to 200mm | 0.02 mm |

01 |

| 05 | Digital Vernier | 0 to 150mm | 0.01 mm | 01 |

| 06 | Micrometer | 0 to 25mm | 0.01 mm | 01 |

| 07 | Vernier Height Gauge | 0 to 300mm | 0.02 mm | 02 |

| 08 | Combination Set | 0 to 300mm | 0.01 |

01 |

| 09 | Plunger & Dial Indicator For Sqness & Ll’ism Checking | 0 to 0.8mm | 0.01 | 02 |

| 10 | Go & No Go Gauges | As per Requirement | -- | 01 |

| 11 | Material Testing Done At S.N. Metallurgical Waluj | Chemical Testing | NABL | 01 |

| 12 | Electronics Load Testing M/C | 0 to 100 Kg | 0.010 Kg | 01 |

| 13 | Load Testing Machine | 0-300 kgf | 0.050 Kg | 02 |

| 14 | Universal Testing Machine | 0 to 40 Ton | 10 Kg | 01 |

Total Production Capacity

| Sr. No. | Machine Name | Code No. | Capacity | Make | Prod./8Hr Shift | Prod/Month in No. |

| 01 | CNC Wire Forming | CM-01 | 0.5 – 3.5mm

|

Imported | 8000 | 200000 |

| 02 | CNC Coiling | CM-02 | 0.5 -3.0mm | Imported | 30000 | 750000 |

| 03 | CNC Coiling | CM-03 | 3.0 – 8.0mm | Imported | 20000 | 500000 |

| 04 | ZIG ZAG Spring M/c | CM-04 | 1.0 5.0mm | Indian | 12000 | 300000 |

| 05 | Coiling M/c. | CM-05 | 1.5 - 6.0mm | Imported | 12000 | 300000 |

| 06 | Coiling M/c. | CM-06 | 1.5 - 5.50mm | Imported | 12000 | 300000 |

| 07 | Coiling M/c. | CM-07 | 1.5 to 5.50mm | Imported | 12000 | 300000 |

| 08 | Coiling M/c. | CM-08 | 0.80 -4.0mm | Imported | 25000 | 625000 |

| 09 | Coiling M/c. | CM-09 | 0.80-3.0mm | Imported | 30000 | 750000 |

| 10 | Coiling M/c. | CM-10 | 0.5- 2.20mm | Imported | 25000 | 625000 |

| 11 | Coiling M/c. | CM-11 | 0.10- 1.50mm | Imported | 30000 | 750000 |

| 12 | Coiling M/c. | CM-12 | 0.10 to 1.20mm | Imported | 30000 | 750000 |

| 13 | Coiling M/c. | CM-13 | 0.80 -3.50mm | Imported | 30000 | 750000 |

| 14 | Coiling M/c. | CM-14 | 1.5 to 8.0mm | Imported | 6000 | 150000 |

| 15 | Coiling M/c. | CM-11 | 3.5 to 12.00mm | Imported | 5000 | 125000 |

| 16 | Coiling M/c.TOR | CM-12 | 1.5 to 6.0mm | Imported | 12000 | 300000 |

| 17 | Coiling M/c.TOR | CM-13 | 0.50 to 2.50mm | Imported | 15000 | 375000 |

| 18 | Coiling M/c.TOR | CM-14 | 0.5 to 2.60mm | Imported | 20000 | 500000 |

| 19 | Grinding | G-1 | 2.00mm-12mm | Indian | 35000 | 875000 |

| 20 | Grinding | G-2 | 2.00mm-12mm | Indian | 7500 | 187500 |

| 21 | Grinding | G-3 | 2.00mm-12mm | Indian | 15000 | 375000 |

| 22 | Grinding | G-4 | 2.00mm-12mm | Indian | 15000 | 375000 |

| 23 | Grinding | G-5 | 1.5 to 6.0mm | Indian | 10000 | 250000 |

| 24 | Furnace | F-1 | 450 °C | Indian | 600 Kg / Hr. | conveyor |

| 25 | Furnace | F-2 | 450 °C | Indian | 300 Kg / Hr. | Box |

| 26 | Shot Pineeing | Sp.01 | 100 Kg /Lot | Indian | ||

| 27 | Shot Pineeing | Sp.012 | 60 Kg /Lot | Indian |